For SMT production lines, feeders are the core auxiliary components of JUKI pick-and-place machines that ensure stable component transmission and high-precision placement. Selecting the matching feeder model for different JUKI machine series, mastering scientific repair methods and adhering to standardized maintenance processes can effectively reduce production downtime, improve material utilization rate and extend equipment service life. This guide comprehensively covers JUKI feeder model compatibility with full machine series, professional repair solutions and detailed maintenance manuals, providing one-stop technical support for your SMT production.

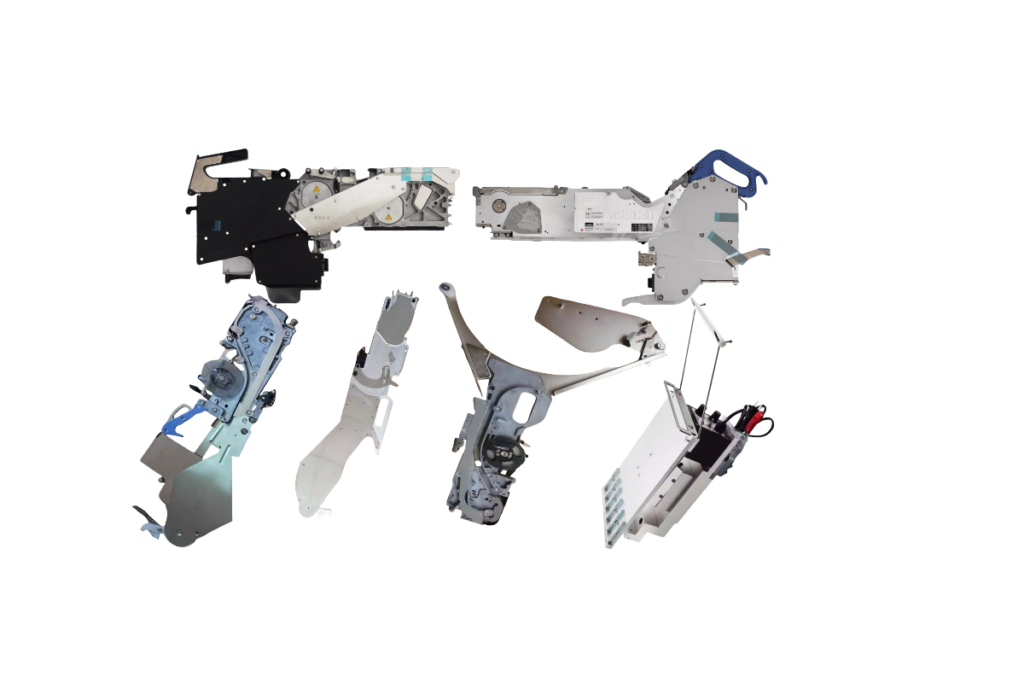

JUKI Feeder Core Classification & Application Overview

JUKI feeders are mainly divided into two categories according to transmission principles, adapting to different component packaging and production demands:

- Tape Feeder: The most widely used type, applicable to tape-packaged SMD components (0201 to large-size ICs), with high transmission stability and fast switching speed, covering most JUKI pick-and-place machine models.

- Stick Feeder: Designed for stick-packaged axial components, matching high-end JUKI series such as RS and FX-3, to realize precise feeding of special components.

Full JUKI Machine Series & Matching Feeder Models (Complete Compatibility Table)

The following table covers all mainstream JUKI pick-and-place machine series including JUKI KE700 Series, JUKI KE2000 Series, JUKI RS Series and JUKI FX-3 Series, with corresponding feeder models to ensure full compatibility matching.

JUKI Pick-and-Place Machine Series Core Applicable Feeder Models Feeder Type Application Scope

JUKI KE700 Series (KE730/KE740/KE750/KE760) CFR 8mm/12mm/16mm/24mm, AF Series, CF Series (CF03/CF05/CF08) Tape Feeder 0201-1206 components, small-size SOP/QFN

JUKI KE 2000 Series (KE2010/KE2020/KE2030/KE2050/KE2060/KE2070/KE2080) CFR Series, CN Series (CN05/CN08), CF8L Series, AF8L Series Tape Feeder + Stick Feeder Multi-spec components, mass production lines

JUKI RS Series (RS-1/RS-1R): JUKI RF08AS Feeder, JUKI RF12AS Feeder, JUKI RF16AS Feeder, JUKI RF24AS Feeder, JUKI RF32AS Feeder, JUKI RF44AS Feeder, JUKI RF56AS Feeder

FX Series (FX-1/FX-1R/FX-2/FX-3/FX-3RA) FX Exclusive CFR Series, High-torque Stick Feeder, CF8L1 Series Multi-type Feeder Flexible production, multi-variety small-batch & mass production

JX Series (JX-100/JX-200/JX-300) Mini CFR Series, JX Special CF Series Compact Tape Feeder Compact production lines, medium-speed placement

Key Model Supplementary Notes: All JUKI feeders are marked with unified specifications, among which 8mm feeders (CF03/CF05/CN05) are for ultra-small components, 12-24mm feeders are for medium-size components, and 32mm+ feeders are for large-size ICs and connectors.

Professional JUKI Feeder Repair Guide (Common Faults & Solutions)

Feeder faults directly affect production efficiency. Master the following targeted repair solutions to solve problems quickly:

- Common Fault 1: Feeder Tape Feeding Jam

- Causes: Gear wear, dust accumulation in the transmission channel, tape guide deviation, spring fatigue

- Repair Steps:

- Disassemble the feeder cover with a professional wrench, clean dust and debris in the gear and channel with alcohol and a brush

- Check gear wear: replace the gear immediately if the tooth surface wear exceeds 0.05mm

- Adjust the tape guide to align with the tape slot, replace the fatigued spring with JUKI original parts

- Reassemble and test the feeding, ensure smooth transmission without jamming

- Common Fault 2: No Component Feeding / Feeding Deviation

- Causes: Vacuum channel blockage, sensor failure, feeding claw wear

- Repair Steps:

- Blow the vacuum channel with an air gun, dredge with a thin steel wire if blocked, and clean with alcohol

- Detect the sensor with a multimeter: replace the sensor if there is no signal output

- Check the feeding claw: polish slightly if there is slight wear, replace if the wear is serious

- Calibrate the feeding position to ensure component alignment accuracy within ±0.02mm

- Common Fault 3: Feeder Cannot Lock to Machine Station

- Causes: Locking buckle deformation, positioning pin wear, connection interface loosening

- Repair Steps:

- Check the locking buckle: correct the deformation with a pliers (avoid excessive force to prevent damage)

- Replace the worn positioning pin with JUKI original accessories

- Tighten the connection interface screw, apply a small amount of anti-loose glue to avoid loosening

- Test the locking function to ensure firm connection without shaking

Standard JUKI Feeder Maintenance Manual (Daily & Regular Maintenance)

Scientific maintenance can extend JUKI feeder service life by 40% and reduce fault rate by 60%. Strictly follow the following maintenance standards:

Daily Maintenance (After Each Shift / 3 Days Cycle)

- Clean the surface and transmission parts of the feeder with an alcohol-soaked cloth to remove solder paste, dust and oil stains

- Check the tape feeding tension: adjust the tension knob to ensure the tape is flat without deformation during transmission

- Test the vacuum tightness: connect the feeder to the machine, check that the vacuum value is within the standard range (-70~-90Kpa)

- Wipe the sensor surface with a dust-free cloth to avoid signal shielding caused by dust

Regular Maintenance (Weekly / Monthly Cycle)

Weekly Maintenance

- Disassemble the feeder gear set, soak in alcohol for 10 minutes, clean thoroughly and dry naturally

- Apply JUKI special lubricating oil to the gear, bearing and transmission shaft to reduce wear

- Check the spring elasticity of the feeding claw: replace the spring if the rebound is slow or weak

- Calibrate the feeder positioning accuracy with a professional gauge to ensure alignment error ≤0.01mm

Monthly Maintenance

- Conduct a comprehensive disassembly inspection of the feeder, replace all worn parts (gear, claw, spring) in time

- Test the service life of the feeder motor: replace the motor if the rotation speed is unstable or the noise is too loud

- Clean the internal circuit board with a dust-free brush, check for loose wires and re-solder if necessary

- Do a full-performance test: ensure feeding speed, accuracy and stability meet production requirements

Long-term Storage Maintenance

- Store idle feeders in a dry, dust-free and temperature-controlled environment (temperature 18-25℃, humidity 40%-60%)

- Coat metal parts with anti-rust oil to prevent oxidation and corrosion

- Classify and store by feeder model, mark clearly to avoid confusion during use

- Conduct a full inspection and test before reuse to ensure normal function

China-Made Compatible JUKI Feeders: Full Interchangeability & Cost Advantages

For SMT manufacturers pursuing cost-effectiveness, our China-made compatible JUKI feeders are ideal alternatives to brand-new original ones. Though not identical to original new feeders in appearance and partial material details, they realize full universal compatibility with all JUKI pick-and-place machine series listed above.

These compatible feeders adopt high-hardness precision gears and wear-resistant transmission components, ensuring the same feeding accuracy (≤0.02mm) and stability as original parts, fully meeting mass production demands. Meanwhile, they offer a more favorable price than original feeders, helping you cut procurement costs by 30%-50% without compromising production efficiency and product yield. Each compatible feeder has passed strict performance testing before leaving the factory, with a stable service life and perfect after-sales support, which is a cost-saving choice for medium and small-sized SMT production lines.

Conclusion

JUKI feeders, with complete models and strong compatibility, are the key to ensuring efficient and stable operation of JUKI pick-and-place machines. By matching the correct feeder model according to the machine series, mastering professional repair skills and adhering to standardized maintenance processes, you can significantly optimize SMT production efficiency, reduce production costs and improve product yield. Our company provides full-series JUKI original feeders and high-quality China-made compatible feeders, as well as professional repair and maintenance services. If you need customized matching solutions, technical support or one-stop procurement services, please contact us at any time.