For SMT manufacturers relying on JUKI pick and place machines, the laser module is the core precision component for component recognition, height detection and placement alignment. A mismatched, misinstalled or poorly maintained laser will directly cause high component rejection rates, tombstoning defects and placement offset, seriously affecting PCB assembly efficiency and product yield. This guide systematically sorts out the laser models matching mainstream JUKI pick and place machine series, and details professional installation standards and maintenance norms, helping SMT teams optimize equipment performance and reduce production downtime.

The core function of JUKI pick and place machine laser is to accurately identify component size, shape, thickness and placement position through laser scanning. It supports high-speed recognition of 01005 ultra-fine components to large-sized BGA/QFP components, ensuring the nozzle picks and places components accurately. .

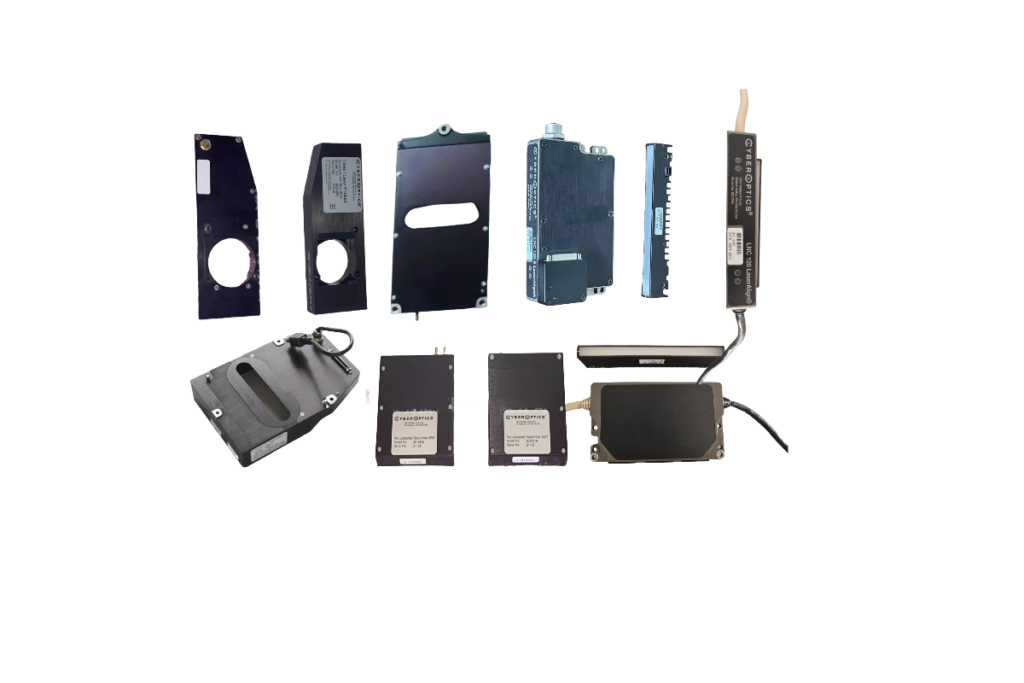

JUKI Pick and Place Machine Laser Classification by Series & Models

- JUKI KE Series Lasers (Classic High-Efficiency Production Line)

The KE series is the most widely used classic JUKI model for medium and large-scale SMT production, with mature laser matching schemes and strong compatibility.

- KE-2050/2060: JUKI MNLA LASER SENSOR E9611729000,model:8000286,8006268,8008000,8010518, which supports recognition of 0402 to 25mm components, with a recognition accuracy of ±0.05mm, suitable for conventional PCB assembly scenarios and FMLA LASER 40003264 CyberOptics 8010519 8005674.

- KE-2070/2080: Adopts upgraded high-speed laser recognition module (LNC60 LASER SENSOR 40045547 CYBEROPTICS 8010398), optimized for high-speed production lines, with a scanning speed increased by 20% compared to KE-2050, and compatible with fine-pitch QFP components.

- KE-3010/3020: Matches the same laser LNC60 module as KE-2070/2080, supporting long PCB production up to 1.2m, which is convenient for enterprises with mixed models to unify spare parts inventory.

- KE-740: JUKI 740 FMLA LASER SENSOR CYBEROPTICS 6604097 E9636729000

- KE-750: Uses compact laser sensor (CYBEROPTICS LASER 6604054), adapted to the small head structure of this model, focusing on small-batch multi-variety production.

- JUKI FX Series Lasers (High-Speed Precision Production)

The FX series focuses on high-speed and high-precision SMT assembly, and its laser modules feature faster scanning speed and higher recognition precision to meet the needs of high-density PCB production.

- FX-1/FX-1R: Equipped with high-precision laser sensor (PN: E9611729000), supporting ultra-fine component recognition of 01005, with an accuracy of ±0.03mm, effectively reducing tombstoning defects of small components.

- FX-2/FX-3: Adopts integrated laser module (LNC60 LASER SENSOR 40045547), integrating height detection and shape recognition functions, which is more stable in high-frequency operation, and is the core configuration for high-end consumer electronics PCB production.

- JUKI JX Series Lasers (Cost-Effective Medium-Speed Production)

The JX series is a cost-effective model for small and medium-sized enterprises, with simple laser structure, easy maintenance and low replacement cost, suitable for small-batch conventional component assembly.

- JX-100/JX-200: Matches entry-level standard laser module (40045547 LNC60 Laser), supporting recognition of 0603 to 20mm components, with a recognition speed meeting medium-speed production needs, and the replacement cost is 30% lower than that of KE series lasers.

- JX-300/JX-350: Uses upgraded laser module based on JX-100, compatible with LNC60 laser of KE series in emergency, convenient for spare part emergency replacement.

- JUKI RS/RX Series Lasers (New Generation Intelligent Production)

The RS/RX series is JUKI’s new generation of intelligent pick and place machines, with integrated laser design, higher integration and stronger anti-interference ability, adapting to intelligent SMT production lines.

- RS-1/RS-1R: Adopts intelligent integrated laser system (CYBEROPTICS LNC 120-8 LASER ALIGN 40182791), matched with the machine’s vision system, supporting automatic calibration and error compensation, with a recognition accuracy of ±0.02mm, suitable for high-precision automotive electronics PCB assembly.

- RX-6/JM20: Use CYBEROPTICS LASER LNC120 40129658.

- RX-7/RX-8: Equipped with ultra-high precision laser sensor (LNC120 Laser), supporting 3D height detection of BGA components, which can effectively avoid placement offset caused by component warpage, and is the core configuration for high-end industrial control PCB production.

Professional Installation Standards for JUKI Pick and Place Machine Lasers

Standard installation is the foundation of stable laser operation, and non-standard operation will cause permanent damage to the laser and affect placement accuracy. Follow these key steps strictly:

- Power off and cut off the air source before installation, and wear anti-static gloves to avoid static electricity damaging the laser circuit board.

- Confirm the laser model matches the machine model, check the laser lens for scratches or dust, and clean the lens with special lens paper if necessary.

- Install the laser in the designated mounting slot, tighten the fixing screws with a torque wrench (torque value: 2.5N·m) to avoid loose installation causing scanning deviation.

- Connect the laser signal cable and power cable according to the wiring diagram, ensure the interface is tightly connected without loosening, to prevent signal interruption during operation.

- After installation, perform laser calibration through the machine operation panel, adjust the laser focus to the standard position, and ensure the recognition accuracy reaches the machine’s factory standard (±0.02~0.05mm based on models).

- Conduct a trial run with 50pcs of standard components, confirm no recognition errors or placement offsets, then put into formal production.

Routine Maintenance & Fault Prevention for JUKI Lasers

Regular maintenance can extend the laser service life to 3-5 years, while neglecting maintenance will cause lens aging and sensor failure in 1-2 years. Follow these maintenance norms:

- Daily Maintenance (After Each Shift)

- Clean the laser lens with special non-dust lens paper, wipe gently in one direction to avoid scratching the lens; do not use alcohol or other corrosive solvents to prevent lens coating damage.

- Check the laser signal cable for wear or loose connection, and clean the laser mounting area to remove dust and solder paste residues, avoiding short circuit of the circuit board.

- Confirm no laser alarm (such as laser dirty error or laser recog error) on the machine panel, and solve the problem in time if an alarm occurs.

- Weekly Maintenance

- Perform laser focus calibration to ensure the scanning accuracy meets the production requirements; adjust the calibration parameters if there is a deviation in component recognition.

- Check the laser heat dissipation fan for normal operation, clean the fan dust to avoid overheating caused by poor heat dissipation, which will damage the laser core components.

- Monthly Maintenance

- Disassemble the laser module for comprehensive cleaning, clean the internal dust and oil stains with dry air, and check the internal circuit for oxidation or damage.

- Replace the laser protective cover (if damaged) to prevent dust and foreign objects from entering the laser interior and affecting the scanning effect.

- Key Fault Prevention

- Avoid laser exposure to strong light or direct sunlight during use, which will cause sensor aging and reduce recognition accuracy.

- Do not touch the laser lens with bare hands, as finger prints will affect light transmission and cause recognition errors.

- If the laser has continuous recognition errors, first clean the lens and recalibrate; if the fault persists, replace the laser module in time to avoid affecting production.

Conclusion

Matching the correct laser model, standardizing installation steps and implementing regular maintenance are the core to ensuring stable operation of JUKI pick and place machines, reducing component rejection rates and optimizing production efficiency. This guide covers the laser matching schemes of mainstream JUKI series from classic KE to intelligent RX, and details installation and maintenance key points, which can help SMT production managers and maintenance personnel solve laser-related problems efficiently.

For enterprises that need to confirm the laser model of special JUKI machines or customize laser maintenance plans, you can contact our professional technical team at any time to get one-stop solutions, and help your SMT production line achieve higher efficiency and better quality.