For SMT production lines, the nozzle is the core component of JUKI pick-and-place machines that determines placement precision and efficiency. Choosing the right JUKI nozzle, mastering standard installation steps and scientific maintenance methods can significantly reduce material throwing rate, improve production capacity and cut maintenance costs. This guide covers all key points of JUKI SMT nozzles to help you optimize your SMT production process.

Core Types of JUKI SMT Nozzles

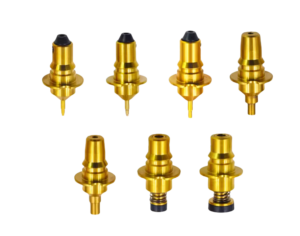

JUKI nozzles are classified by application scenarios and component sizes, mainly divided into two core categories to meet diverse SMT production needs:

- Standard Suction Nozzles: The most widely used type for common SMD components (0201 to large-size BGA). Made of high-hardness ceramic and metal materials, it features strong wear resistance and stable vacuum adsorption, which is the first choice for mass production lines.

- Special-shaped Custom Nozzles: Designed for non-standard components such as high-power inductors, large-size connectors and irregular-shaped components. It adopts a clamping or special adsorption structure to solve the problem of difficult pickup of special components and realize zero error placement.

Full List of JUKI SMT Nozzle Models & Application Scope

JUKI nozzles are numbered in a unified standard, and each model corresponds to specific component sizes, covering all mainstream SMD components in the industry. The full models and core application scenarios are as follows:

- JUKI KE750/KE760 Nozzle: 101 Nozzle(0201), 101 Nozzle(0402), 102 Nozzle, 103 Nozzle, 104 Nozzle, 105 Nozzle, 106 Nozzle, 201 Nozzle, 202 Nozzle, 203 Nozzle, 204 Nozzle

- JUKI KE2010/KE2020/KE2030/KE2040/KE2050/KE2060/KE2070/KE2080/FX-1/FX-1R Nozzle: JUKI 500 Nozzle, JUKI 501 Nozzle, JUKI 502 Nozzle, JUKI 503 Nozzle, JUKI 504 Nozzle, JUKI 505 Nozzle, JUKI 506 Nozzle, JUKI 507 Nozzle, JUKI 508 Nozzle, JUKI 509 Nozzle, JUKI 510 Nozzle , 511-535 (JUKI Special Nozzle)

- JUKI gripper Nozzle: JUKI 800 gripper nozzle, JUKI 801 gripper nozzle, JUKI 802 gripper nozzle, JUKI 803 gripper nozzle, JUKI 804 gripper nozzle (for large-size special components).

- JUKI RS-1/RS-1R nozzle: JUKI 7500 Nozzle, JUKI 7501 Nozzle, JUKI 7502 Nozzle, JUKI 7503 Nozzle, JUKI 7504 Nozzle, JUKI 7405 Nozzle, JUKI 7506 Nozzle, JUKI 7507 Nozzle, JUKI 7508 Nozzle, JUKI 7509 Nozzle.

- RX-6/RX-7/RX-8 Nozzle: HF0402R(C) Nozzle, HF0603R Nozzle, HF0603R(C) Nozzle, HF1005R, HF1005R(C) Nozzle, HF10071 Nozzle, HF10071(C) Nozzle, HF12081 Nozzle, HF12081(C) Nozzle, HF25201 Nozzle, HF1608R Nozle, HF3216R Nozzle, HF35171 Nozzle.

- JUKI Customize Nozzle for different components.

This complete model system ensures that JUKI pick-and-place machines can be compatible with almost all SMD components on the market, realizing flexible switching of multi-variety and small-batch production.

Standard Installation Steps for JUKI Nozzles

Correct installation is the premise of stable operation of nozzles. Follow these steps to avoid placement deviation and nozzle damage:

- Pre-installation Check: Confirm that the nozzle model matches the current component, and check the nozzle tip for deformation, wear or rubber pad loss to ensure no blockage inside.

- Fixed Installation: Align the nozzle with the mount head interface, press it firmly until a “click” sound is heard, and manually rotate it to confirm that it is locked without loosening.

- Post-installation Verification: Start the machine’s automatic nozzle detection function to check the height, vacuum tightness and position accuracy. Only after passing the test can production be started.

- Key Note: Do not use brute force to install or disassemble the nozzle to avoid damaging the mount head and nozzle connection structure.

Professional Maintenance & Maintenance Suggestions for JUKI Nozzles

Scientific maintenance can extend the service life of JUKI nozzles by 30% and reduce the production shutdown rate caused by nozzle problems. The core suggestions are as follows:

Daily Maintenance (3-5 Days Cycle)

- Clean the nozzle regularly: For 502-504 small nozzles, soak them in alcohol for 5-10 minutes and blow dry with an air gun; for 505-508 large nozzles with rubber pads, wipe the surface with alcohol-soaked cloth to avoid rubber pad falling off caused by full soaking.

- Check the vacuum channel: Use a thin steel wire to dredge the blocked nozzle channel, and blow it clean with an air gun to ensure smooth air flow and stable vacuum.

Regular Inspection (Weekly Cycle)

- Check the nozzle tip for wear and deformation. If the tip is worn more than 0.1mm or deformed, replace it in time to avoid component throwing and offset.

- Test the spring elasticity of the nozzle manually. Press the nozzle 10 times to confirm that the rebound is flexible without jamming, and apply a small amount of JUKI special No.1 grease to the spring part.

- Clean the nozzle station nest with alcohol cloth to remove oil and dust, and avoid inaccurate positioning during nozzle switching.

Long-term Storage Suggestions

- Store the idle nozzles in a dry and dust-free environment, and classify them by model to avoid confusion.

- Coat the metal part of the nozzle with anti-rust oil to prevent oxidation and corrosion during long-term storage.

Conclusion

JUKI SMT nozzles, with complete models, high precision and strong adaptability, are the core guarantee for efficient SMT production. By selecting the right nozzle model, following standard installation processes and adhering to scientific maintenance, you can maximize the performance of JUKI pick-and-place machines, reduce production costs and improve product yield. If you need customized special-shaped nozzles or matching solutions for JUKI nozzles, please contact us in time to get professional one-stop services.